Research and Development

innovative production processes

Research and Development to support innovation

D’Agostino Industry adopts cutting-edge automation processes to guarantee more efficient production and develop technological solutions that optimise output, reduce energy consumption and prevent waste.

The research and development team at D’Agostino Industry is committed to developing optimised, sustainable production. The company invests a significant amount in human resources and technology, in order to explore new frontiers and develop innovative industrial automation systems.

Constant research allows the company to adapt to changes in the market and customer needs. Through constant research into new materials, innovative production processes and state-of-the-art design ideas, D’Agostino Industry is committed to constantly improving the performance of our systems.

Italian technology for the food industry

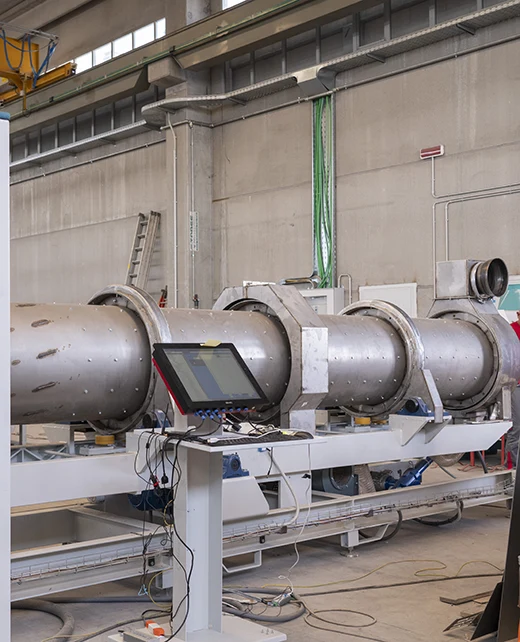

D’Agostino Industry stands out for its experience in the design and creation of machines and systems for the processing of a wide range of products. The company integrates the latest digital technologies to optimise production, improve product quality and guarantee maximum operational efficiency. Thanks to technical skills and specialised know-how, D’Agostino Industry offers customised solutions that are able to meet the specific needs of customers.

Use of systems projected towards Industry 5.0, equipped with advanced sensors and automation

The design office creates prototypes and 3D designs using SolidWorks software. The systems used allow real-time data collection on processes, safety and machine performance. Equipped with built-in electrical panels, they offer the possibility to manage and monitor plants remotely in order to guarantee prompt assistance and reduced production downtime.

Industrial processes for a more sustainable future

D’Agostino Industry adopts cutting-edge processes and develops sustainable technological solutions that optimise production, reduce energy consumption and protect the environment. The company is committed to making sustainability a fundamental part of the production cycle, implementing practices that respect the environment and promoting a circular economy.

The spray booth uses powdered paints with a low environmental impact, and is equipped with powerful filters that absorb the paint particles in the air and circulate clean air.

Water consumption is optimised through collection and conservation of water resources, in order to guarantee responsible, sustainable water use.

Metal waste is reinserted into the production cycle wherever possible. Non-reusable waste is disposed of following strict procedures, or sold to third parties for further use.

Industrial revamping service to upgrade a plant's old electrical parts to more modern, higher-performance components.

Dependability and precision

Constant attention to quality and customer care has made the company a leading name in the sector.

Technological expertise, qualified staff, high-quality production and continuous improvement are D’Agostino Srl’s foundational values. For over 50 years, the company has offered products that guarantee customers absolute safety in operations. Every component of our systems is built with high-quality materials and fine-tuned with precision to ensure optimal performance and a long life. Our team of experts provides assistance and technical support to customers, allowing them to operate in safety, with complete peace of mind.